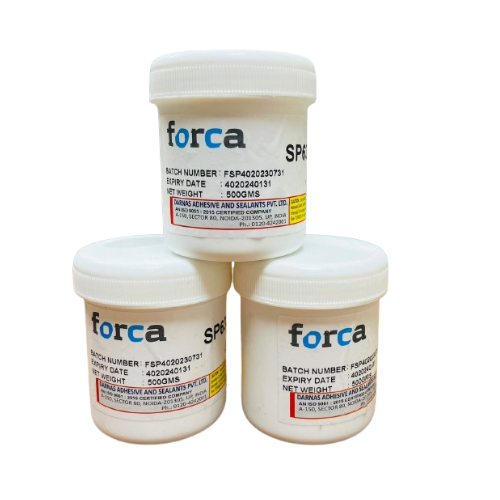

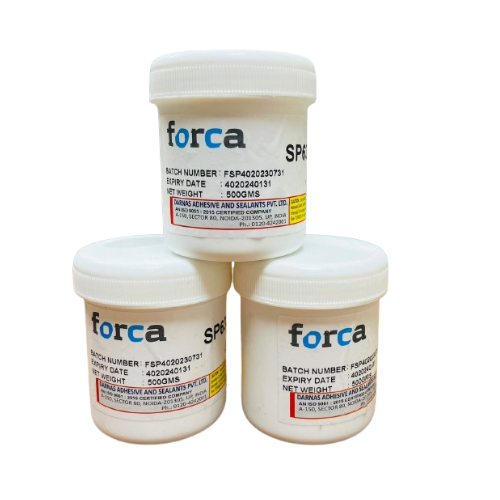

Solder Paste

DARNAS Solder Paste Suppliers in Electronics Manufacturing

if you are in SMT industry and finding best solder paste manufacturer and suppliers for your electronics Manufacturing needs then you are in right platform. because paste few years we are working in this segment very sensorily to make high end quality solder paste for modern and technology based smt electronics manufacturing process.

Solder paste suppliers play a pivotal role in the electronics manufacturing industry, providing essential materials and support to ensure the success of surface mount technology (SMT) processes. Here are some key functions these suppliers fulfill:

Expert in Solder paste manufacture and Development

DARNAS invest in research and innovation to create new formulations and improve existing ones, with technological advancements and industry standers. invest in eco-friendly manufacturing processes, recycling waste reduction strategies to minimize pollution and conserve natural resources.

Our manufacturing Team will We work Closely with our Smt electronics manufactures to understands there needs and our Research Team Develop Solder paste solutions for our channel partners need and trying to meet specific application requirement, to help high reliability soldering paste.

Committed Quality Assurance solder paste supplier

DARNAS committed to Supply good quality solder paste and equipped with advanced machinery and processes to produce solder paste to the highest quality standards. also measures are implemented throughout the soldering process to ensure consistency and reliability of the soldering paste products.

Technical Support and Training

DARNAS also play a multiple role in supporting electronics manufacturers and suppliers by offering them technical support, expertise and training to managing supply chains efficiently, and promoting environmental responsibility. our Team also provide training programs, workshops, and seminars to educate customers on best practices for storage and usage of solder paste effectively.

By partnering with reputable solder paste suppliers, electronics manufacturers can enhance electronics soldering processes, achieve higher productivity, and deliver superior-quality electronic products to the customers.

Type of solder paste ?

Solder paste is a crucial material used in surface mount technology (SMT) processes to printed circuit boards (PCBs). There are several types of solder paste available in the market let see most common types of solder paste where DARNAS is facing on.

Leaded Solder Paste

Leaded solder Paste formulations contain two important constituent 1st Tin and 2nd Lead. Lead-based solder pastes also know as 63/37 leaded solder paste. Because this solder paste contain 63% of Tin and 37% of lead. Have been widely used in electronics manufacturing for decades due to their excellent wetting properties, reliability, and ease of use.

However, environmental concerns and regulatory requirements, such as the RoHS directive, have led to the gradual phase-out of lead-based solder paste in many regions.

Leaded Solder Paste is a type of solder paste and this paste mainly used in printed circuit board (Pcb) and other electronics components. Ther leaded soldering paste a mixture of tiny solder particles in the form of tin lead (sn-pb) alloys. And this alloys mostly used in electronics assembly over a long period of time because of their excellent soldering capability thermal conductivity and easy to use.

Leaded solder paste has low melting point because of that it easier to work during reflow soldering processes leaded solder also create smoother solder joints and reducing the risk of defects like = solder bridges and tombstoning.

Lead Free Solder Paste

Lead free solder paste is becselly top rated quality paste the reason behind this manufacturing component use in the paste. This paste contains various of metals and alloys. The most common components use to make this paste superius is Tin(sn), copper (cu) and silver (ag) and elements.

1st is Tine(sn) the majority composition ranging around 90% to 99%by weight. And higher tin content generally results in low melting point and better wetting characteristics.

2nd copper (cu) copper is improving pastes mechanical strength and thermal conductivity. And copper usually ranges from 0.15 to 2%by weight.

3rd silver (Ag) silver is also very important metal in lead free pastes to enhanced strength and conductivity. Silve typically useage ranges from 0.1% to 4%by weight. Its also depending on formulation and application requirements.

Best Quality Solder Paste manufacturer and suppliers in India.

Quick Links

Darnas adhesive and sealants Pvt. Ltd. Address:- 150, Block A, Sector 80, Noida, Uttar Pradesh 201305

WhatsApp no : 7838031300 / 9650806989

Email : sales@darnas.in

© 2021, All rights reserved with Darnas adhesive and sealants Pvt. Ltd